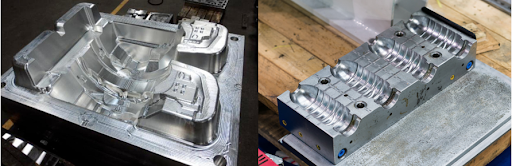

Deciding between steel and aluminum for your injection tooling material is crucial as they both have their unique benefits to the production process. It is always important to consider the different options, as the requirements for every project vary, and choosing the suitable material is essential in manufacturing.

This article discusses the criteria for choosing each mold type when applying plastic injection molding services, the pros and cons, and a detailed comparison between aluminum and steel tooling.

Why Tooling Materials Matter in Parts Production

Each mold material has their specific properties and applications. Therefore, for best results, you must choose the most suitable materials according to your project requirements.

Though the differences between steel and aluminum tooling are not significant, it is enough to cause problems if not chosen correctly. Selecting appropriate materials for tooling ensures a smooth manufacturing process. Production size and production speed are also critical factors considered in determining suitable tooling materials.

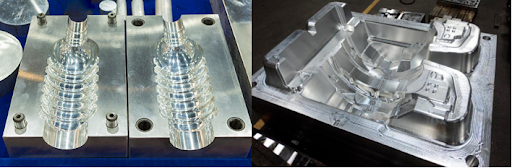

How To Choose the Right Plastic Injection Molding Tooling?

Many factors determine the proper tooling for a specific project as each mold material has its uniqueness and characteristics. Below are the factors used to determine the appropriate tooling.

-

Low Volume VS High volume

Aluminum is more suited and gives better value for low-volume production runs that do not run into millions. This material has lesser upfront costs; it can produce parts in thousands and tens of thousands with minimum wear and tear. So, for production parts needed within days or a few weeks, aluminum is a good option.

For high volume and multiple production runs, steel is your best bet. Production from steel molds runs into millions of parts with optimum quality. The initial higher investment cost rewards you in the long run with equipment that lasts for years with proper care. The strength of steel also improves its compatibility for longer production runs. So, constantly assess your project specifics to ensure that the right tooling for the material is used.

-

Part Materials

The part material is a factor which impacts the life expectancy of the tool and is critical in deciding the tooling. Will it be a mild material or an aggressive one, or a material that withstands a high amount of heat?

Both steel and aluminum fit an extensive range of injection molding resins. However, steel is better suited for more complex formulations like glass, fiber, and other additives.

Aluminum is softer than steel and is at greater risk of being damaged by certain additives and abrasive resins, affecting the final parts’ finish. Also, texture selection is limited when tooling with aluminum because of its low density.

-

Budget (Tooling Cost & Cost per Part)

In terms of the cost of manufacturing injection molded parts, aluminum tooling is more cost-effective compared to steel. The value and return on investment for both molds vary depending on the utilization of the mold. Aluminum tooling requires lesser initial investment costs than steel and offers better value for low production volume.

Cost per part depends on the intended production run and the lifespan you want from your parts. For shorter production runs, aluminum is the better option, as the lower upfront costs of the molds lead to lower costs per part. If your production volume runs into millions or tens of millions, investing in steel molds is appropriate. The cost per part pays off in the long run because of the longer service time the mold provides.

-

Time (Tooling Time & Heat and Cooling Time)

Aluminum tooling transfers heat from the mold quicker; therefore, it heats and cools about seven times much faster than steel molds. It also has faster machining time, reducing mold-build time.

Cooling time takes up the bulk of overall cycle time in injection molding. Using aluminum mold when appropriate saves cycle time, leading to faster production of parts. Timing depends on factors such as design complexity, surface characteristics, and inserts for special features.

-

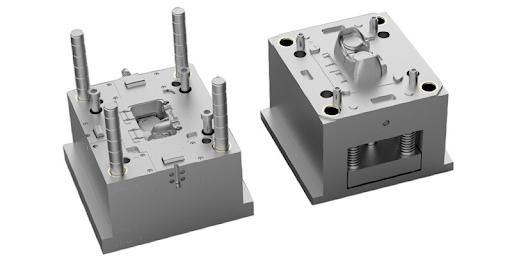

Durability

Steel tooling far surpasses aluminum when it comes to durability due to its immense hardness and superior strength. It can withstand periods of repeated use. So, this makes it the best fit for high-volume production. The high upfront investment of the mold also pays itself back over the repeated use.

On the other hand, aluminum tooling is not as durable, and the molds become susceptible to wear and tear after production cycles of a few thousand.

-

Part Size and Complexity

The size and geometry of the parts affect the choice of molding. Steel molds are more suitable than aluminum for parts that require a more polished and complex design like thin walls, less rounded angles, etc.

The strength and hardness of steel make it more capable of holding a shape in high precision areas. Steel molds support parts complexity. Steel molds offer more finishing options for surfaces compared to aluminum which is ideal for simple designs.

-

Shrink, Warp, and Other Defects

Aluminum has superior heat dissipation. Therefore, it enables the mold to achieve uniform heating and cooling times faster. It also minimizes the amount of faulty or rejected parts. Non-uniform heating and cooling are a significant cause of defects such as sink marks and voids. The faster heat dissipation by aluminum also decreases the number of parts rejected due to shrink wrap and other defects. Thus, this gives aluminum molds better cost advantages because of the reduced rejection rates of parts.

-

Tooling Modifications and Maintenance

Damaged steel molds are tough and expensive to repair because of the hardness of the materials. Engineers typically restart with a new mold should any production error occur. On the other hand, aluminum molds are easier to modify and repair. This is because they are made from softer materials that can be adjusted in case of any production error.

Conclusion

Deciding on the right plastic injection molding tooling is a vital decision during production and depends on factors such as; cost, part materials, production volume, time, maintenance, and time. It is necessary to be fully aware of your project’s overall requirements and specifications before commencing manufacturing, as they serve as a guide to picking the proper tooling for your project. The right tooling decision can save you both time and money.